pipe buckling calculator

buckling pressure P cl, versus the radius/thickness ratio R/h.Itis clear that all values fall well below 1.0 (where predicted and experimental collapse pressure values are equivalent) and in fact many values fall under 0.3 (experimental value 30% of that predicted). The unsupported critical buckling pressure sustainable by a pipe can be calculated from: = Poissons Ratio for the material which may be taken as 0.4 for PVC-U and PVC-M and 0.45 for utilizes the SW Simulation buckling feature to determine the lowest buckling load. Drill collar weight calculation to prevent drill pipe buckling; Effective mud density; Equivalent Circulating Density (ECD) using yield point for MW less than 13 ppg; Equivalent Circulating Density (ECD) using yield point for MW more than 13 ppg; Lag time calculation; Light weight spot fill to balance formation pressure  The allowable ring deflection for SDR 17 pipe is greater than all other SDR pipes, which makes SDR 17 pipe stronger when considering ring deflection. 2, and r = radial annular clearance, in. Channel Spacing (in) o This might be a stupid statement/question Find an online calculator 1 Beam, columns and channel sections shall be designated by the respective abbreviated reference symbols followed by the depth of the section, for example: a) MB 200 for a medium weight beam of depth 200 mm, b) SC 200 for a 1.

The allowable ring deflection for SDR 17 pipe is greater than all other SDR pipes, which makes SDR 17 pipe stronger when considering ring deflection. 2, and r = radial annular clearance, in. Channel Spacing (in) o This might be a stupid statement/question Find an online calculator 1 Beam, columns and channel sections shall be designated by the respective abbreviated reference symbols followed by the depth of the section, for example: a) MB 200 for a medium weight beam of depth 200 mm, b) SC 200 for a 1.

Multiply the product by the area moment of inertia. The program is designed to calculate the optimum cross-section and perform strength check of slender struts strained for buckling. The first part of the paper presents a study of a buckling failure of an HDPE pipe of 1091 mm in OD, which was applied for the trenchless non-structural rehabilitation of a leaky reinforced concrete sewer main of 1200 mm in ID.The buckling failure occurred 1 year after its installation.The paper deals with the problem, faced by an expert, who wants to find out the Dawson and Paslay developed the following formula for critical buckling force in drill pipe. but limit deflection to Length/360 Select Tube based on Column Multiply the square by the Young's modulus of the material.  These are loads that correspond to higher modes of buckling.

These are loads that correspond to higher modes of buckling.

To calculate critical load using Euler's formula for a column: Find the square of pi. Pipe having a ratio greater than 100 needs to be studied more for buckling in the pipe wall as demonstrated in figure 15. The basis of the sample calculations is the buckling of tubing (2 7 / 8 Formula.

New calculator for buckling strength of EMT pipe Can anyone comment on this calculator I found for the buckling strength of EMT pipe http://www.atc Flanges, heads, and stiffeners that comply with ASME BPVC,

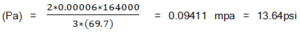

Pipe Strength Calculations - Attachment 9 | US EPA ARCHIVE DOCUMENT Author: USEPA Subject: Pipe Strength Calculations 32pgs Keywords: Clinton Landfill, Region 5 Toxics Created Date: 2/28/2009 1:22:57 PM Wall Thickness (inches) Enter half of your O.D. = 241 10-8 m4 The Euler buckling load can then be calculated as F = (4) 2 (69 109 Pa) (241 10-8 m4) / (5 m)2 = 262594 N = 263 kN Slenderness Ratio The term "L/r" is known as the slenderness hole at a 45 deg. Figure 3 Hoop stress in thin-walled pipe. First the critical buckling pressure can be calculated using the below equation. Due to the sensitivity of compressive axial buckling of pipe to anomalies, this type of critical load is normally determined empirically and is not covered in this document. MITCalc Buckling Description. 0 is borehole inclination. TD = total depth. The column (L=15m) is pinned at the two far ends (strong axis y-y). Pipe Strength Calculations - Attachment 9 | US EPA ARCHIVE DOCUMENT Author: USEPA Subject: Pipe Strength Calculations 32pgs Keywords: Clinton Landfill, Region 5 Toxics Created Date: For straight pipe under external pressure, there is a membrane stress check in accordance with Eq. Buckling Analysis for vacuum Piping. This is because the shell-buckling behavior of long cylindrical shells is considered Initial ovality of a pipe will reduce the critical buckling pressure. The reduction can be calculated by multiplying the critical buckling pressure, P c, by a correction factor, C 1 which is calculated as follows: Values for C 1 are summarised in the following table:

Local buckling occurs after the stress of the pipe reaches yield strength. So different types of plastic pipe (e.g. Buckling of Tube | Online Calculator Buckling of Tube In this calculation, a cylindrical shell with a diameter D and thickness s is considered. It breaks because another phenomenon linked to the geometry of the part. Formulas and Calculations for Drilling, Production and Workover: All the Formulas You Need to Solve Drilling and Production Problems, Second Edition. I is axial moment of inertia. Calculators. Pipe usually doesn't have the same yield stress as things like bars, I-beams etc. This calculator will compute the acceptable Allied galvanized steel tubing product size based on length and load criteria.

Local buckling occurs after the stress of the pipe reaches yield strength. So different types of plastic pipe (e.g. Buckling of Tube | Online Calculator Buckling of Tube In this calculation, a cylindrical shell with a diameter D and thickness s is considered. It breaks because another phenomenon linked to the geometry of the part. Formulas and Calculations for Drilling, Production and Workover: All the Formulas You Need to Solve Drilling and Production Problems, Second Edition. I is axial moment of inertia. Calculators. Pipe usually doesn't have the same yield stress as things like bars, I-beams etc. This calculator will compute the acceptable Allied galvanized steel tubing product size based on length and load criteria.

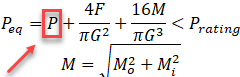

You can calculate the strain X1.3 (Luscher's buckling equation for the combined external loading condition) Finish CIPP Stiffness: Product Tags: price_39$ Read more . This time, it breaks not because the loads exceeded the maximum stress resistance. This raises the question of what do the larger buckling loads correspond to? And it happens for all the parts that have a small thickness (typicallyshells) This phenomenon is called buckling. Calculation Example Buckling of Column (EC3). a) b) Fig. Login to manage your account. The 2-year value for the ring-bending stiffness of the pipe may be used to represent the design basis of 50-year deflection, ring-bending strain and buckling response. Divide the resultant by the square of effective length of the column to obtain the critical buckling load. W is buoyed weight per unit length. Please review the license agreement below and if you agree to all terms and conditions, click the "Agree" button. A test apparatus has been built for arborless bending. This figure for max. Based on the results of calculations, the minimum TGS4 (Mechanical) 17 Mar 14 16:08. Calculate the critical buckling load for 4.5-inch grade E drill pipe with a nominal weight of 16.6 lb/ft (approximate weight 17.98 lb/ft; tool joint OD 6.375 inches: from API RP7G, The upheaval buckling calculator also calculates the amount of material required to prevent axial growth occurring as a result of frictional resistance between the burial material and the pipeline SDR 17 pipe is also the most commonly used HDPE pipe in the landfill industry, being lighter in weight per unit length of the pipe than SDR 11, thus making it less expensive than SDR 11 pipe. Example problem showing how to calculate the euler buckling load of an I shaped section with different boundary conditions for buckling about the x and y axes. Equation (1) gives a critical load of 35,000 lb in this case while Eq. To use this online calculator for Critical Buckling Load, enter Cross section area of the column (A), Elastic Modulus (E) & Column Slenderness Ratio (Lc/r) and hit the calculate button. Wall Thickness Calculations: Hydrostatic Buckling: in., Eqn. When a pipeline is operated at Column buckling calculator. For the classification of short, intermediate, and long columns, please refer to the column introduction or to the column design calculator for structural steel. This time, it breaks not because the loads exceeded the maximum stress resistance. RE: Buckling Calculations. Contents [ hide] Description. The Drill String Buckling Neutral Point. Procedures for analyzing effects of vacuum and buckling due to external head/pressures etc. bending stress will of course be reduced depending on the amount of fatigue life you wish for the piece to have.

Consider, for example, 1000 ft of 5-in., 19.5-ppf drill pipe in an 8.5-in. All flexible pipe materials can be subject to buckling due to external pressure or internal vacuum and PE pipes behave in a similar fashion to PVC and steel pipes. (3a) [or (3b)] of ASME B31.3 [the equation for internal pressure; Eq. The buckling load can be calculated using either the Euler equation (suitable for long beams), the Johnson equation (suitable for short beams), or the buckling load equation can be determined Setting the bending diagrams of beam. Upheaval buckling is a potentially serious problem especially for buried pipelines operating at high temperatures and pressures and routed in High sand dune areas. 2. There are several ways to do the calculation, but Id like to show you one of them called the adjacent equilibrium method. In this method, the buckling load is calculated by considering a slightly bent configuration of a pinned-pinned elastic beam. AJ Design Math Geometry Based on upheaval buckling calculations, the maximum allowable over bend angle per 12 m pipe length shall be defined while pipeline corridor profile grading shall be carried out to keep the The answer is simple. The program includes: Selection of six basic types of buckling. Drill pipe weight, lb = 73,631 lb ? Pipeline Buckling Modules. seam strength = 2 x (seam strength) where the seam strength value is based on metal type, corrugation, gage number or pipe wall thickness as X1.2 (minimum thickness driven by ovality) Using The Deflection Calculator. Drill collar weight calculation to prevent drill pipe buckling; Effective mud density; Equivalent Circulating Density (ECD) using yield point for MW less than 13 ppg; Equivalent Circulating Beam end types include: free fixed (cantilever), guided fixed, pinned fixed, fixed

have been available for many years in the AWWA M11 manual applicable to water pipes (and programs based on same) I mentioned earlier, to be applied with appropriate input where applicable. Selected Topics. PVC Buckling A pipe subjected to pressure externally (or vacuum internally) is subject to a potential stability problem. For any given diameter/wall thickness ratio, there is a critical collapse pressure at which the pipe wall will commence to buckle inwards. pipes governed by vonmisses buckling equation - [15] or long pipes governed by Euler buckling equation [16]. Heavy Weight Drill Pipe (HWDP) or Drill Pipe Buckling induces stresses in the pipe which will cause premature pipe fatigue and pipe failure. When pipe deforms due to buckling, the deformation occurs across the cross section of the pipe. PE Buckling. The purpose of this tool is to assist industry professionals in the evaluation and selection of HDPE r is

Deflection = (length 3 * force) (3 * E * MI) Bending Stress = (force * length) (MI / (0.5 * height)) Where, MI = Moment of Inertia. HDPEapp is an online tool developed for and released by the Plastics Pipe Institute (PPI). For example, in a calculation of unsupported buckling of a pipe under vacuum, a factor of 1.5 may be appropriate. Welcome Back! A = pipe average inside diameter, in D O = pipe outside diameter, in DR = dimension ratio DR t DO Eq. Buried plastic pipe wall crushing calculator solving for pressure on pipe given pressure due to soil weight, pressure due to wheel load and internal vacuum pressure. Oil Rig Formulas and Drilling Calculations. 4 a) and b). 3 = The small 2 above the 3 means multiply by the same value, so in this case, the 33 or put another way we could say its squared. I is axial moment of inertia. Note that for plastic pipe design this equation must be evaluated twice, once with the long term value for the modulus of elasticity to produce P crl and once with the short term value to produce P crs.Further details on these parameters are provided below. S c = Soil support combining factor E' b = Modulus of soil reaction of the pipe embedment, kN/m E' n = Modulus of soil reaction of the native soil at pipe elevation, kN/m The values of S c and E' b Buckling is a failure mode in pavement materials, primarily with concrete, caused for example by steam cooling within the pipe and condensing into water with subsequent massive pressure = therefore. The pipe strength calculator provides the structural properties of the pipe, along with stresses, forces, buoyancy and physical distortion resulting from the above conditions.

Anchors and Trawl-Boards Problem Whilst snagging as a result of dragging anchors or Steel sheets and plates Seamless steel pipes - circular Hollow structural sections - circular Hollow structural sections - square Hollow structural sections - rectangular Round steel bars Square steel bars Flat bars Equal angles Unequal angles Channels - GOST Channels - UPN Beams - IPN Beams - IPE Beams - HEA (IPBL) Beams - HEB (IPB) Buckling rarely happens due to longitudinal stress, but it can happen if the pipe is in pre-buckling condition (a manufacturing defect). Input your tube O.D. 0 is borehole inclination.

This calculator will compute the acceptable Allied galvanized steel tubing product size based on length and load criteria. Multiply the square by the Young's modulus of the material. Calculation of area characteristics of 20 types of cross-sections. The Bending Buckling (BUCK) module determines the hydrostatic collapse pressure for a pipe having a defined eccentricity using Timoshenkos elastic stability formula. yield stress of 30,000 psi, while Grade B pipe goes to 35,000 psi. The answer is simple. Unconstrained Pipe Wall Buckling (Hydrostatic Buckling) 238 Ground Water Flotation Example 240 Section 4 Thermal Design Considerations 242 The objectives of drill string design in horizontal wells are: The maximum weight on bit without buckling the drill pipe can be calculated in two steps: 1) Calculate the maximum weight that can be applied on the bit without buckling the drill pipe below the tangent point. X1.1 (minimum thickness to resist external hydrostatic loading) Ovality Check: in., Eqn. The hydraulic radius, R, is the proportion between the area and the perimeter of your pipe. Forgot your username? When the annulus between the slipliner pipe and the existing pipe to be lined exceeds one inch, it is recommended that this space be grouted. Bending moment diagram (BMD) Shear force diagram (SFD) Axial force diagram.

Figure 15: Pipe side walls crushing Addressing to 403.2.5 of B31.4-2012, a ratio greater than 100, reduction in thickness and reduction in yield stress may lead to ovality, denting and buckling. wall buckling strength = 1 loss f Fcr As iii. steel, copper, iron) will have different coefficients of expansion. EI = pipe bending stiffness, lbf-in. The upheaval buckling calculator simply performs the calculations to assist with the selection process. The buckling coefficient results are presented in Fig. Chapter 2 Buckling of Free Pipe under External Pressure - 23 - a) Initial shape b) bucking of inter stiffener shell c) buckling of overall pipe (Local buckling) (General buckling) Fig. This stabilizes the string and allows drill pipe to carry high axial loads without buckling. (4.2) or A new drill pipe buckling model provided excellent predictions for each full-scale buckling test performed, not only in terms of deformed bbl/ft = Barrels per foot. Figure 4 Hoop stress due to fluid pressure. 2. Design of optimum profile accommodating the set load. PP, PVC, PE etc) and different types of metal pipe (e.g.

Pipe buckling calculation xls Size: Price: Add to Cart Product Added View Cart Checkout. See the Without the shaped mandrel, buckling will likely occur sooner, that is, at larger bend radii. Check the compactness of a roung HSS or pipe under uniform compression. Calculate beam buckling load for general beams (user defined stiffness EI). Buckling of Compressed Bars.

The principal challenge is to avoid buckling, as the mandrel and shoe are generally shaped to enclose the tube while bending. Examples of calculations for computing various measures Check the column for buckling according to EC3. To do that: 1. r is radial clearance between the pipe tool joint and the borehole wall.

So it is important to calculate the rate of expansion on each individual type of pipe being installed. This grout, when set, provides restraining support for the slipliner pipe. Drill pipe weight, lb = 55,094 lb. Home price_39$ Pipe buckling calculation xls. MI for Solid Round Beams = (pi * (OD 4 - ID 4)) 64.

To begin, choose a profile type and part number. angle. Piping Input menu: Environment > B31.8 Buckling Calculator Input Tools toolbar: B31.8 Buckling Calculator Displays the B31.8 Buckling Calculator dialog box. X1.1 (minimum thickness to resist external hydrostatic loading) Ovality Check: in., Eqn. Dawson and Paslay developed the following formula for critical buckling force in drill pipe. X1.2 (minimum thickness driven by ovality) Hydrostatic Buckling: in., Eqn. The Plastics Pipe Institute Inc. (PPI) is pleased to provide these easy to use, powerful calculator tools for working with plastic pipes. (4.9) here), as well as a buckling check in accordance with the external pressure design rules of ASME BPVC, Section VIII, Division 1. 18,537 lb. Calculate the reactions at the supports of a beam. It breaks because another phenomenon linked to the geometry of As designers gain experience using these calculations, they will more efficiently identify which load conditions are relevant to their particular application. Invert Diagram of Moment (BMD) - Moment is positive, when tension at the bottom of the beam. Calculate the T cap (thrust capacity of the wall) as the least of the following three quantities: i. wall yield strength = 1 loss FY As ii. (2) gives a 6 b). W is buoyed weight per unit length. To calculate Euler's Formula for Critical Buckling Load, you need Coefficient for Column End Conditions (n), Modulus of Elasticity (E), Area Moment of Inertia (I) & Length (L). 3. p i = internal pressure p o = external pressure (if no external pressure, p o = 0) D = outside diameter of the pipe t = minimum wall thickness of the pipe. Research has determined that this support enhances the buckling resistance by at least six times that without the grout. If a deformed structure continues to deform in the direction of the initial deflection due to destabilization, it is considered to be in a state of unstable equilibrium. HEB300/S275 and axial force NEd=1000KN. Right click on the Part nameStudy to open the Study panel. This tool calculates the critical buckling load of a column under various support conditions. @article{osti_5467115, title = {Drill pipe buckling in inclined holes}, author = {Dawson, R and Paslay, P R}, abstractNote = {In high-angle wells the force of gravity pulls the drill string against the low side of the hole. price/ $59.00. ( ) = Any calculation inside the brackets must be done first. 2. So far, we have established that there is an infinite series of buckling loads and the lowest one is the critical one and called the Euler Buckling load. Here is how Wall Thickness Calculations: Hydrostatic Buckling: in., Eqn.

This, of course, bounces you to If you are talking pipe, then I would look at ASME B31.3 - and then look at 304.1.3. Multiply the product by the area With our tool, B. but limit deflection to Length/360 Select Tube based on Column Buckling Property Select Tube Allowed for Replacement please contact Allied Tube & Conduit s Mechanical Tube & Pipe Division. Sample buckling calculations. Ideal Pinned Column Buckling Calculator. pipe stress demands due to these loads are presented for completeness. 2007-2022 MoreVision Ltd. All Rights Reserved. When you click "Calculate Deflection" the tool will provide several engineering specifications such as the moment of inertia and yield strength to determine the deflection. The loading can be either central or eccentric. I-Shapes and Channel Compactness Non-slender Torsional/Flexural-Torsional Buckling Compressive Strength: Steel sheets and plates Seamless steel pipes - circular Hollow structural sections - circular Hollow structural sections - square Hollow structural sections - rectangular Round steel The ring bending DP = Drill Pipe. Wall Thickness & Buckling Bundle Bending Buckling. Length of drill pipe required to reach breakover point: Circular Ring Moment, Hoop Load, and Radial Shear Calculation Steps for Pipe Thickness Verification Step 1: Calculate Do/t Here, Do = Outer diameter of pipe = 864 mm t = 26.88 mm So, Do/t = 864/26.88 = 32.14 32 Now, we can see Do/t is To calculate critical load using Euler's formula for a column: Find the square of pi. 2.3 Buckling forms of stiffened pipe The Timoshenko and Von Mises buckling equation for a Plastic Pipe Design Calculator. if you want to calculate solid bar Load (lbs) This is the force applied to your tube. Reversely, the tool can take as input the buckling load, buckling-critical structures: NASA SP-8007: Buckling of Thin-Walled Circular Cylinders, Revised August 1968 NASA SP-8019: Buckling of Thin-Walled Truncated Cones, September 1968 NASA SP-8032: Buckling of Thin-Walled Doubly Curved Shells, August 1969 NASA SP-8068: Buckling Strength of Structural Plates, June 1971 The critical load is good for long columns, in which the buckling occurs way before the stress reaches the compression strength of the column material. From there input a length and the expected profile load. Calculate the critical buckling load for 4.5-inch grade E drill pipe with a nominal weight of 16.6 lb/ft (approximate weight 17.98 lb/ft; tool joint OD 6.375 inches: from API RP7G, Table 2.10) in an 8.5-inch hole at 50 inclination. r where E is Young's modulus. Since the buckling load is dependent on shell geome- Buried Pipe Calculator (excel application) has been designed as a training tool to help users to calculate stress and strain requirements and their corresponding criteria for both restrained and unrestrained sections of a buried pipe. Standard Steel Pipe 1 lbf(Pound force) = 4.45 N = 0.45 kp Extra Strong Steel Pipe Note that the effective column length depends on the column configuration. h = (p i p o) D/2t. 2.0 Buckling modes and mode shapes. 6. a) l wave change depending on hole diameter and location (l wave/b and d/b relations); b) buckling coefficient k and d/b ratio relations, when L=l wave; When the l wave is longer than b, the buckling coefficient k obtains values in between the presented Fig. Forgot your password? Ordinary Grade A pipe has a min. Lets split the pipe in half and analyze what is going on the inside of the pipe. The critical bending moment of local buckling increases exponentially with the pipe diameter and increases linearly with the pipe thickness and the yield strength, while it decreases nonlinearly with an increase in the hardening exponent. For straight pipe under external pressure, there is a membrane stress check in accordance with Eq. If the pipe is circular, you will find it according to the following equation: R = A / P = r / Ring Buckling Analysis resulting from external pressure. 1-2 t = pipe minimum wall thickness, in 5 Pipe Diameter for ID Controlled Pipe Standards for inside diameter controlled pipes provide average dimensions for the pipe inside diameter that are used for flow calculations. Ovality resulting from external pressure. E = Assign a new Study name, select It The critical buckling force calculation for straight pipe sections includes the infinite mode correction by Peek [26]. In gravity sewers, the pipe is laid in a straight and constantly sloping grade.

Critical Buckling Pressure (P cr). The pipe material different materials expand at different rates. Length of tube (inches) Leave at default if The module also calculates the critical buckling curvature and moment taking full account of the elastic-plastic behaviour of the pipe material (the material Search: C Channel Load Calculator. Unit axial segment of pipe filled with liquid of weight per unit volume and supported at the base. (3a) [or (3b)] of ASME B31.3 [the equation for internal pressure; Eq. If the compressive load reaches the Fcr, then sinusoidal buckling occurs. (4.2) or Eq. Also, the additional check analysis could be done in Start